RBI Value: Both Transitioning And From The Start

by Michael Hurley, 1/21/2021 Be the first to commentTags: Mechanical Integrity Process Safety Management Risk Based Inspection Risk Management

This article deals with the value of going directly to an Risk Based Inspection (RBI) program from nothing or transitioning from a time/condition based program and demonstrates that an RBI program is the efficient use of resources.

Whether you find yourself with a mature time/condition based mechanical integrity (MI) program or have no program at all, moving to a Risk Based Inspection (RBI) program can have value. These are two ends of the spectrum, with regard to mechanical integrity, that many of us find ourselves on.

We will not discuss the challenges and possible opportunities that moving to an RBI program will provide. That will be covered in one of our upcoming videos in our YouTube series on RBI.

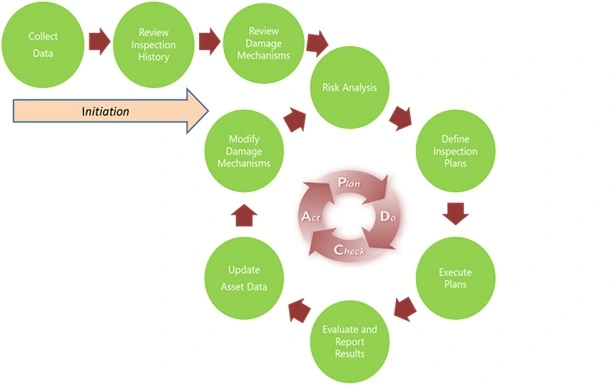

We will discuss the value gained by moving from either end of the spectrum as previously described. In order to do this, we need to work from a common work process for both time/condition based, and risk based programs. Therefore, let us look at a typical Mechanical Inspection process shown below:

While this only seems to be related to RBI, it is also the same work process for time/condition based MI. To make it time/condition based MI, the "Risk Analysis" bubble needs to be removed or bypassed. The latest U.S. API inspection codes, as well as other codes around the world, are requiring that inspection tasks must address all "anticipated" damage mechanisms. Therefore, the only difference is whether you use a risk prioritization.

Let us perform a thought experiment. In this experiment we have 100 pressure vessels which are carbon steel. These vessels fall under the jurisdiction of OSHA, Process Safety Management (PSM) regulations. Every vessel is uninsulated, and they operate at less than 350 °F. Let's assume that the cost of the average inspection regardless of type is $5,000. This amount includes all maintenance and production support and will be summed for only one inspection of each type or one inspection cycle. If we also assume that the only damage mechanisms for this equipment are:

- Internal Corrosion

- External Corrosion

Using time/condition based MI each inspection plan would contain three (3) tasks to address the damage mechanisms above:

- Internal Visual (VI-Int) Inspection

- Ultrasonic Thickness (UT) Inspection

- External Visual (VI-Ext) Inspection

Therefore, the costs for one inspection cycle for a time/condition based MI program would be:

| Inspection Type | Number of Inspections | Cost per Inspection | Cost per Inspection Type |

| Internal Visual (VI-Int) Inspection | 100 | $5,000 | $500,000 |

| Ultrasonic Thickness (UT) Inspection | 100 | $5,000 | $500,000 |

| External Visual (VI-Ext) Inspection | 100 | $5,000 | $500,000 |

| Total Cost All Inspection Types, 1 Inspection Cycle, time/condition based MI | $1,500,000 |

AOC's leadership team, having been in the business of implementing RBI programs for over 20 years, maintains a set of expected inspection reduction factors for downstream assets by inspection type. This data comes from past RBI implementation projects and is shown below:

The difference between the red and aqua bars is the reduction factor. The percentage of equipment required to be inspected for a time/condition based MI program under PSM are the red bars. The percentage of equipment required to be inspected for an RBI program under PSM are the aqua bars. As can be seen from the bar graph above, piping and relief device inspections can be reduced more than the fixed equipment.

Using the table and bar graph from above, the costs for one inspection cycle for an RBI program would be:

| Inspection Type | Number of Inspections | Cost per Inspection | Cost per Inspection Type |

| Internal Visual (VI-Int) Inspection | 62 | $5,000 | $310,000 |

| Ultrasonic Thickness (UT) Inspection | 63 | $5,000 | $315,000 |

| External Visual (VI-Ext) Inspection | 46 | $5,000 | $230,000 |

| Total Cost All Inspection Types, 1 Inspection Cycle, time/condition based MI | $855,000 |

This shows a savings of $645,000 per inspection cycle. What does this mean for transitioning from a mature "time/condition based MI program" to RBI? It means that there is a savings per inspection cycle of $645,000 after the transition.

Now let us look at the spectrum's other end, "no program at all". Knowing this, we need to extend our thought experiment with a further assumption:

- All the inspections for all inspection types are overdue or have never been performed.

What does this mean for transitioning from "no program at all" to RBI? This means that instead of having to immediately go out and inspect all 100 pieces of equipment for all damage mechanisms, you might have to only inspect a smaller percentage suggested in the "Total Cost All Inspection Types, 1 Inspection Cycle, RBI" table immediately above. The experiment's savings of $645,000 is justified as the greatest number of inspections required to put it into compliance using RBI is 63 instead of 100. However, the savings might be even greater when the experiment's risk profile is calculated, and the risk levels are tackled by inspecting equipment one risk level per year.

Therefore, it seems obvious, that the old adage "walk before you can run" should not apply to your MI program. The thought experiment above proves that whether you are starting from scratch or transitioning from an existing time/condition based program, the most efficient use of resources is to use an RBI program.

Add your comment

Related Services

An interdependent assessment of your people, process, and technologies for a confident path forward

Asset Integrity Management for all asset families - Rotating, Electrical, Instrumentation, and Fixed Assets

AOC has delivered thousands of sustainable Risk Based Inspection (RBI) programs earning the trust of owner operators.

Related Tools

Create mechanical integrity (MI) program value rather than it being seen as a necessary cost to minimize.

How well do you know RBI? Take this short quiz to test your knowledge of the API 580 risk-based inspection (RBI) work process.

Is your plant's MI program compliant? Use our checklist to assess your current program against industry standards and receive expert recommendations for improvement.

Related Training

A high level overview introducing Mechanical Integrity and Risk Based Inspection

What impact does Risk Based Inspection (RBI) have on my organization?

Is your Risk Based Inspection (RBI) program aligned with the API 580 Recommended Practice? Are you ready for certification?

What's actually going on inside all of that fancy software? An introduction to the API 581 methodology.

A deep dive into quantitative Risk Based Inspection (RBI) as outlined in API 581.

Related Knowledge

Budget tight? Some Risk-Based Inspection (RBI) risks are too critical to delay. Learn the top 3 RBI risks that can't wait for a budget rebound.

This is a practical approach to incorporating the new PHMSA gas well rules into your integrity program with the rest of your surface and subsurface assets.

A dysfunctionality found in many refineries, chemical plants, and other production facilities, is a lack of common asset management work processes.

Transitioning to Risk-Based Inspection (RBI) delivers measurable efficiency and cost savings, whether you have a mature Mechanical Integrity (MI) program or are starting from scratch. See a simple 100-vessel example saving $645,000 per cycle.

An update to our original proposal for an API 581 Inspection Plan optimization.

A look at how the financial sector's concept of Asset Value Management can be applied to the petrochemical industry.

An example to compliment our earlier proposal for a risk analysis option that allows for individual damage mechanism risk calculation in API 581

A proposal for a risk analysis option that allows for individual damage mechanism risk calculation in API 581

PHMSA has out for comment, draft document information, that clarifies its jurisdiction in relation to OSHA for Midstream Processing Facilities.

Can Non-Intrusive Inspection (NII) finally replace vessel entries? Explore the roadblocks to RBI, validated POD data for UT and RT, and a new framework for technical equivalency in modern refinery maintenance.

- 2018

- 2019

- 2020

- 2021

- 2024

- 2025

- 2026

Comments

There are no comments for this article.