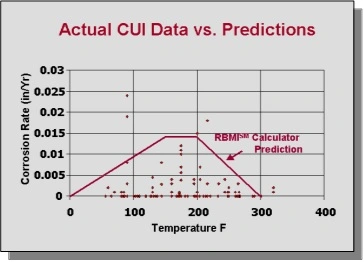

A 25 year old chemical plant in the Gulf Coast United States was experiencing an increase in Corrosion Under Insulation (CUI) failures of their insulated equipment and piping. Because of these failures, the facility recognized that implementing a CUI program for these assets was key to understanding and preventing this type of failure. Through the implementation, the facility also needed a prioritized inspection and maintenance list as a way of completing the tasks in a safe and fiscally responsible manner.

RBI consultants put together a plan for a Risk Based Inspection (RBI) program for the insulated assets that would address the needs of the facility. Asset data was collected, along with a review of the previously performed inspections, to perform a damage mechanism review based on the CUI damage mechanism. Using these results, risk was evaluated on the insulated assets and inspection plans were developed. Visual and NDE inspections were completed and the risk of each asset was reevaluated to develop a 10 year inspection plan.

The results of the CUI program implementation were that all the insulated equipment and piping was brought into a manageable CUI program, with a prioritized list of future inspections base on current and future risk. The facility also had maintenance recommendations that were prioritized and based on a multi-year budget, which included insulation and piping replacement and vessel repairs. Additionally, all of the completed prioritized inspections found more than a dozen imminent failures.

Case Study Inquiry