Operational Readiness and Maintenance Strategy Development

For years, AOC consultants have been delivering sustainable and reliable asset performance management programs to ensure operational readiness based on RBI (risk-based inspection) and RCM (reliability-centered maintenance) studies. Our successful approach aligns your people, processes, and technologies so that you implement best practice risk-based work processes and increase the design life of your assets months ahead of RFSU.

People

Our learning management approach strengthens a sense of ownership in your personnel through the systematic transfer of knowledge of training, human performance improvement, work processes and technology. As a result, you are equipped to implement best practice risk-based work processes and to increase the design life of your assets months ahead of RFSU.

Process

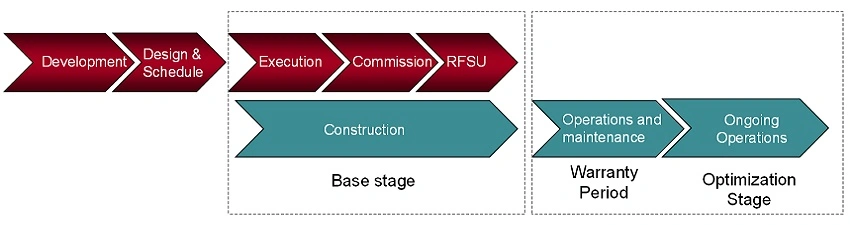

We begin with the end in mind: OME (Operation, Maintenance and Engineering) services end when the EPC (Engineering Procurement and Construction) contractor hands the plant over to the Owner following acceptance of the performance test. We work proactively with you and your EPC to develop maintenance strategies for operational readiness, optimized recommendations, and activity plans during EPC to facilitate the activities of the contractor and Owner prior to and after plant handover.

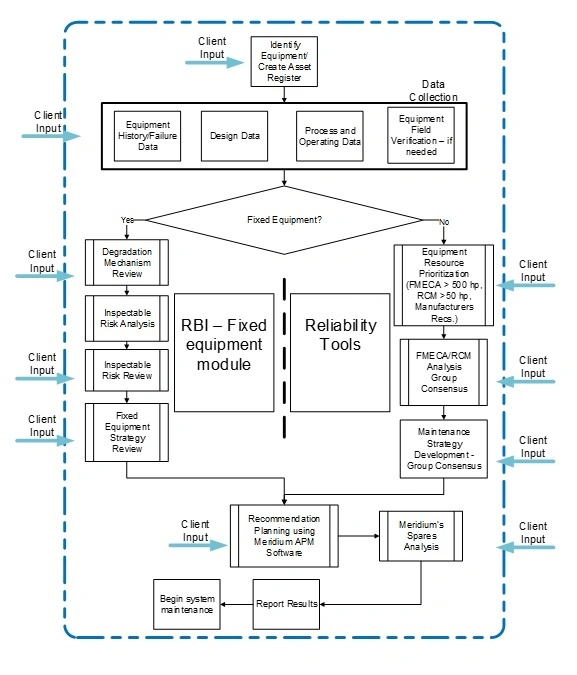

A simplified overview of that process is as follows:

This process includes the analysis of equipment types to develop a Risk Ranking for each inspectable component. A consequence of failure (CoF) analysis is performed based on safety/environmental implications from loss of containment as well as production loss models to approximate business interruption. An estimate of the probability of failure (PoF) is based on the identified degradation mechanisms and deterioration rates affecting the equipment.

For rotating assets and components, we use FMECA and RCM techniques to determine failure modes affecting the asset. Since these techniques are resource intensive, a prioritization scheme is developed so that only the most economically critical assets/components are analyzed. For example, a preliminary approach might be based upon power of the rotating driver as follows:

- Assets/Components greater than or equal to 500 hp will be analyzed using FMEA.

- Assets/Components less than 500 hp but greater than or equal to 50 hp will be analyzed using RCM.

- Assets/Components less than 50 hp may not be analyzed at all but follow standard manufacturers maintenance recommendations.

Technology

Our consultants help to select and populate data into your CMMS and AIM (asset integrity management) software solution using technologies such as Intergraph's Smart Plant and Fusion to facilitate data migration from those "sources of truth" to the target database of those selected technologies. If these technologies have yet to be selected, we deliver one map that aligns all of the requisite manufacturing, design and operating data into an ISO 14224 compliant database.

Related Services

Asset Integrity Management for all asset families - Rotating, Electrical, Instrumentation, and Fixed Assets

AOC has delivered thousands of sustainable Risk Based Inspection (RBI) programs earning the trust of owner operators.

Innovative technology that allows quick, efficient extraction of data into a knowledge-centric world

Related Tools

Create mechanical integrity (MI) program value rather than it being seen as a necessary cost to minimize.

Is your plant's MI program compliant? Use our checklist to assess your current program against industry standards and receive expert recommendations for improvement.

Related Training

How do I use GE APM to perform MI/RBI tasks?

How important are they?

A high level overview introducing Mechanical Integrity and Risk Based Inspection

How does GE APM RBI software estimate risk?

How do I use RBMI to perform MI/RBI tasks?

Related Knowledge

Most PSM loss-of-containment events stem from execution failures, like deferred repairs and ignored inspections, rather than a lack of technical knowledge. Learn why organizational accountability is the key to preventing major accidents.

A dysfunctionality found in many refineries, chemical plants, and other production facilities, is a lack of common asset management work processes.

A look at how the financial sector's concept of Asset Value Management can be applied to the petrochemical industry.

A proposal for a risk analysis option that allows for individual damage mechanism risk calculation in API 581

"Good inspection" is not defined by technical tools, but by a leadership choice to allow the truth about equipment condition to surface. Learn why management is the most critical variable in mechanical integrity.

Is your inspection program reducing risk or just checking boxes? Learn why 100% coverage doesn't guarantee safety and how to shift your focus from activity to true assurance.

The U.S. refining industry recorded nine significant fires and explosions in 2025. While the count is low, incidents at Chevron and HF Sinclair highlight the critical need for robust mechanical integrity and process safety programs.

Can Non-Intrusive Inspection (NII) finally replace vessel entries? Explore the roadblocks to RBI, validated POD data for UT and RT, and a new framework for technical equivalency in modern refinery maintenance.

Why companies overlook Mechanical Integrity: It's expensive, exposes risk, requires specialized knowledge, and is difficult to audit. Learn the 10 structural, cultural, and economic reasons MI is the weakest PSM element.

Discover why equipment failure is the root cause of most catastrophic incidents. Mechanical Integrity (MI) is the non-negotiable foundation that prevents loss of containment and protects your entire PSM system. Learn the 8 reasons MI is essential.

Service Inquiry