A criticality assessment was conducted on a Storage Tank Farm in Seabrook Texas. The project involved an RBI assessment of 14 pressure vessels, 2 heat exchangers, 108 storage tanks, 888 piping circuits and 187 relief devices. A total of 17 items were found to have a "High" rating. The distribution of overall criticality ratings for the items in scope is summarized as follows.

| DISTRIBUTION OF CRITICALITY RANKINGS | ||||||

|---|---|---|---|---|---|---|

| Overall Criticality Category | ||||||

| Equipment Type | Equipment Count | Component Count | High | M-H | Medium | Low |

| Piping Circuits | 888 | 888 | 0 | 117 | 94 | 677 |

| Fixed Equipment Components | 124 | 340 | 15 | 63 | 54 | 208 |

| Relief Devices | 187 | 187 | 2 | 42 | 96 | 47 |

| Totals | 1,199 | 1,415 | 17 | 222 | 244 | 932 |

Seventeen items were in the "High" Criticality category due to a combination of internal and external corrosion. The relief devices are High because of the deterioration potential based in part on last inspection date

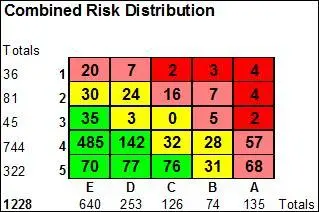

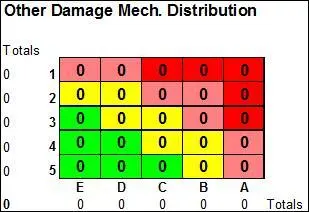

Risk Distribution by Damage Mechanism

The following shows the Criticality Matrix for this facility with the number of equipment item components in each block. These represent all of the equipment types included in the study. The Probability of Failure Rankings are on the vertical axis and range from "1" (Very High Probability) to "5" (Very Low Probability). The Consequence of Failure Rankings are on the horizontal axis and range from "A" (Catastrophic) to "E" (Minor).

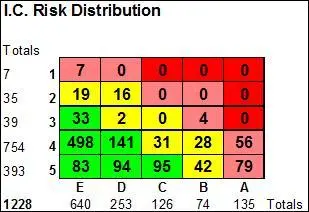

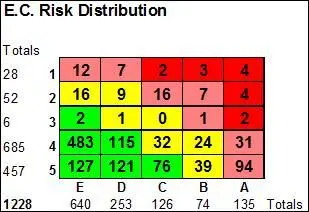

Probability of Failure

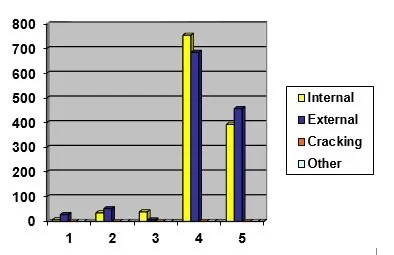

The following figure separates the probability of failure count by internal corrosion and external corrosion, stress corrosion cracking and other mechanisms. Internal and external corrosion and SCC are the major factors contributing to the higher probabilities.

Probability of Failure by Damage Mechanism

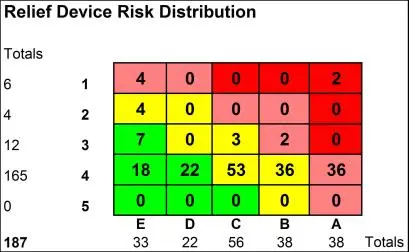

Probability Analysis for Pressure Relief Valves

The Criticality Rating considers both the probability and consequence of failure categories. The probability of failure is based on the failure mode "failure to relieve at design pressure", which covers the most important failure scenario. The probability category is established by considering the potential for internal corrosion, fouling and plugging. Credit is given when a rupture disk protects a relief valve. Interviews with operations personnel and reviews of the shop test reports are used to determine the deterioration potential. The potential and the time interval since the last shop overhaul are used to determine a deterioration factor, which is converted directly into a probability of failure category. This study revealed that many of the pressure relief devices were in "like new" (4) condition.

The Probability of Failure Rankings are based on valve history, length of time in service, and the potential for fouling or plugging.

The Consequence Rankings are based on the highest consequence of failure of the protected equipment items.

Consequence of Failure

| Unit | Rank | Equipment ID | Component | Reason for HIGH |

|---|---|---|---|---|

| Bay 19 | 1 | 31-19-050-T-050-01 | Storage Tank Shell | External Corrosion |

| Bay 19 | 2 | 31-19-050-T-050-01 | Roof | External Corrosion |

| Bay 19 | 3 | 31-19-052-T-052-01 | Storage Tank Shell | External Corrosion |

| Bay 19 | 4 | 31-19-052-T-052-01 | Roof | External Corrosion |

| Bay 17 | 5 | 31-17-098-T-098-01 | Storage Tank Shell | External Corrosion |

| Bay 04 | 6 | 31-04-031-T-031-01 | Storage Tank Shell | External Corrosion |

| Bay 04 | 7 | 31-04-030-T-030-01 | Storage Tank Shell | External Corrosion |

| Bay 17 | 8 | 31-17-096-T-096-01 | Storage Tank Shell | External Corrosion |

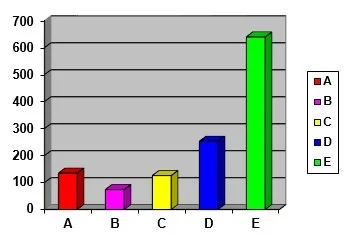

For all components in the study, the consequence analysis was modeled as a release of a fluid from the pressure-containing boundary to the atmosphere. The consequence analysis utilized models that consider flammable, toxic, inert and reactive consequences. The Consequence Ranking Distribution for all components is shown graphically in the following Figure.

Inspection Work Plan Summary

Inspection plans were generated for all equipment items in the study. Each plan included the Equipment ID, Inspection Priority Ranking, all potential damage mechanisms associated with each item and the suggested inspection method to address each damage mechanism. The following represents the proposed inspection work plan for the highest risk items found in the study. The next step in managing the RBI program in this unit is to follow through the recommended inspections. Then for items found to be in the Higher Criticality Categories, establish a plan for managing them. Some of the items can be addressed very quickly; others have to wait until the next shutdown. The table below lists the HIGH Criticality items, the mechanism responsible for the HIGH Risk and a general inspection recommendation.

| Unit | Rank | Equipment ID | Component | Reason for HIGH |

|---|---|---|---|---|

| Bay 19 | 1 | 31-19-050-T-050-01 | Storage Tank Shell | External Corrosion |

| Bay 19 | 2 | 31-19-050-T-050-01 | Roof | External Corrosion |

| Bay 19 | 3 | 31-19-052-T-052-01 | Storage Tank Shell | External Corrosion |

| Bay 19 | 4 | 31-19-052-T-052-01 | Roof | External Corrosion |

| Bay 17 | 5 | 31-17-098-T-098-01 | Storage Tank Shell | External Corrosion |

| Bay 04 | 6 | 31-04-031-T-031-01 | Storage Tank Shell | External Corrosion |

| Bay 04 | 7 | 31-04-030-T-030-01 | Storage Tank Shell | External Corrosion |

| Bay 17 | 8 | 31-17-096-T-096-01 | Storage Tank Shell | External Corrosion |

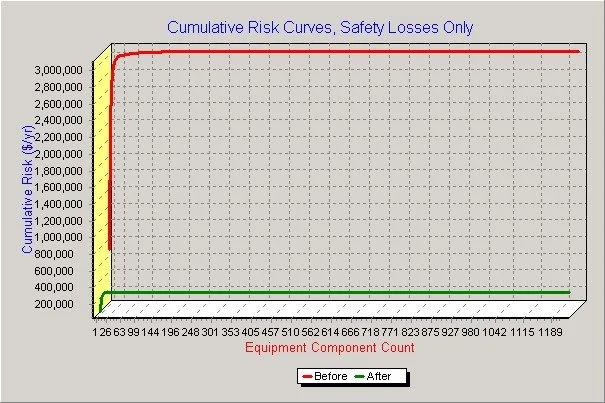

Risk Reduction

The following shows the projected risk reduction in dollars per year as a result of focusing inspections on the higher criticality items. For this analysis, it was assumed that the risk reduction would result from addressing the highest 8 (1%) of the fixed equipment items in the study, resulting in a 90% risk reduction of nearly $2,500,000 per year.

Conclusion

The above provides insight into the results of an RBI study across a number of fixed equipment asset families, relief devices and piping circuits. In addition to the significant risk reduction delivered ($2.5M annually) from an RBI program, cost savings can be realized by a factor of 50% for vessel inspections and up to 75% for piping inspections. Typical turnarounds can be optimized and internal inspections of less critical assets extended allowing refiners to realize millions in USD in T/A savings.

Case Study Inquiry