"Anything worth, doing is worth doing right."

Hunter S. Thompson

To begin with, let us examine some of the goals of these companies stated in their project requirements documents along with the resulting solutions:

Company A

-

GOAL: To achieve zero corrosion related loss of primary containment across our refining enterprise

-

SOLUTION: Develop a corrosion control plan including five major components:

- Corrosion and Materials Diagram

- Corrosion Control Document

- Integrity Operating Windows

- Risk Based Inspection Assessment

- Risk Based Inspection Strategies

Company B

-

GOAL:

- Meet our Process Safety Management (PSM) standards and more stringent local requirements

- Meet asset management requirements for Mechanical Integrity as outlined in the five year PSM plan submitted to HSE

- Understand risk in the plant, reducing unexpected failures on critical equipment

- Demonstrate significant value

-

SOLUTION: Achieve our site goal through Risk Based Inspection and continue across our enterprise

Company C

-

GOAL:

- Less incidents and releases that can affect our employees and our neighbors

- Increased Operational Asset Utilization (OAU) for the site

- Lower reactive maintenance costs

- Better relations with our neighbors

- Sense of "Proud Ownership" by all the employees because they know that the facility is taking reasonable and required steps to ensure their safety and the safety of the community by ensuring that the equipment used in the process is fit for service today as well as tomorrow

ADDITIONAL QUESTIONS NEEDNG ANSWERS:

- Do we understand the threats facing our plant?

- Do we know the equipment integrity risks?

- Will the RBI program find and fix problems before they become BIG EVENTS?

- Are we inspecting the right things and do we use the right inspection methods?

- What are others doing to improve their integrity management programs?

- How much will it cost to achieve better reliability?

- How do we measure the value of the program?

- How do we measure and motivate the people managing our program?

-

SOLUTION:

- Transition service provider project to a company owned program

- Track performance using KPIs and reports i.e. Cumulative Risk curves as a leading indicator

- Align lagging indicators with leading indicators tracked by RBI program

-

Process Safety Related Incidents

- Environmental releases

- Loss of Containment events

- Unscheduled Production Interruptions

Many, if not all, the above GOALS and subsequent SOLUTIONS were achieved in many cases by utilizing the technology to create the relevant reports. Making the reports meaningful, however, requires additional effort with people, process and technology. We align roles and responsibilities with work processes and key performance indicators.

To affect a sustainable asset integrity management program, we worked with each client to develop a set of work processes that fit their organization. We then defined the roles and responsibilities required to successfully effect the work process along with a set of meaningful metrics to measure both the performance of the program, which included similar KPIs to the goals defined above and a set of skills validation tools to measure the on-going performance of the personnel managing the program.

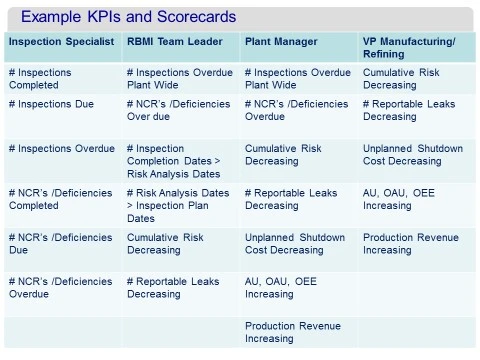

An example of these "role based" KPIs can be seen in the below Cascaded KPI scorecard, provided to one of our refining clients. Once we were all aligned, AOC addressed and training and performance development of the workforce to fulfill the defined roles and responsibilities. The technology was then programmed to accommodate the needed dashboards and KPI reports to facilitate the work process.

In conclusion: How do we as asset performance management consultants measure success? What are our KPIs? Repeat business is a good measuring stick, as well as great reputation in those industries served.

Case Study Inquiry