Reliability Based Asset Management - AIM for all asset families

The Problem

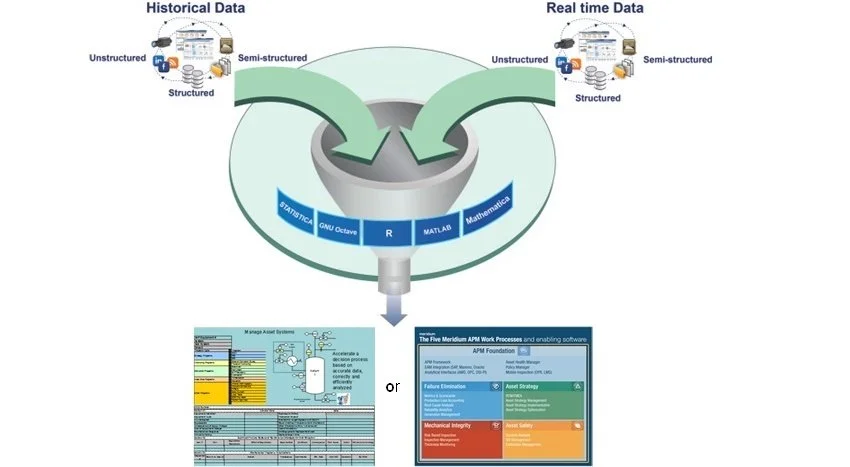

Maintenance and Reliability are highly dependent on having accurate, consistent and compliant Asset Data. In addition, design, operating data and documentation are essential for effective, safe, and efficient asset integrity management. But owner-operators struggle to manage large volumes of unstructured information that resides in silos across the organization.

A Possible Solution

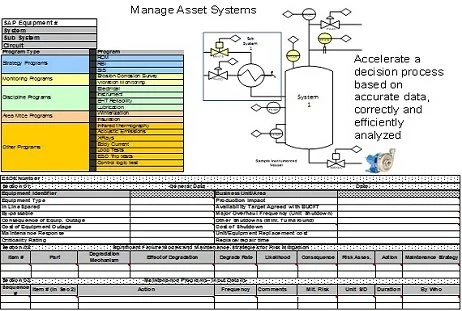

Many owner-operators have resorted to spreadsheets to pull the requisite asset data, work processes and procedures needed to take a systems view of reliability across multiple asset families.

A Better Solution

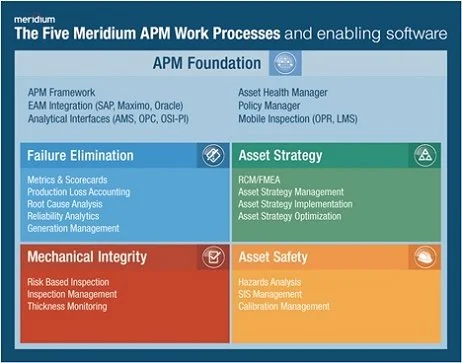

But it is the interdependencies and integrated results of managing this information that allows technology to facilitate good decision making, especially during an unplanned event and subsequent startup of a downed process unit.

The Delivery Model

In addition to GE APM (Meridium), AOC has teamed with Intergraph using their rule based technology, Fusion, to expedite converting the unstructured docu-centric world of the refinery or chemical manufacturing facility, to the data-centric world of Smartplant.

And when dealing with disparate technologies and databases, we have teamed with Rolta and their OneView universal connector framework to provide enterprise integration capabilities to integrate these disparate systems using a Service Oriented Architecture (SOA).

The result is a simplified and expeditious methodology for delivering risk based asset management across all asset families.

The delivered Solution

It is your choice - we will show you:

- how to get there

- how long it will take

- what it will cost

- what the value will be to your company

- how it will exceed your target Return On Net Assetes (RONA)

and

We will deliver the total asset integrity management solution

...as a spread sheet or as an integrated, sustainable asset performance management program. Whether you are in the early stages of design or a brown field site and/or enterprise looking to dramatically improve plant availability, we can deliver an integrated asset integrity management program across all your asset families. For more detail please contact us.

Related Services

Development of maintenance strategies, recommendations, and plans to implement best practices and increase asset life

An interdependent assessment of your people, process, and technologies for a confident path forward

AOC has delivered thousands of sustainable Risk Based Inspection (RBI) programs earning the trust of owner operators.

Related Tools

Create mechanical integrity (MI) program value rather than it being seen as a necessary cost to minimize.

How well do you know RBI? Take this short quiz to test your knowledge of the API 580 risk-based inspection (RBI) work process.

Is your plant's MI program compliant? Use our checklist to assess your current program against industry standards and receive expert recommendations for improvement.

Related Training

A high level overview introducing Mechanical Integrity and Risk Based Inspection

What are your goals for RBI? How will you measure your success? How will you sustain that success?

Developing the value proposition and business case for an RBI program

How important are they?

What impact does Risk Based Inspection (RBI) have on my organization?

Related Knowledge

A dysfunctionality found in many refineries, chemical plants, and other production facilities, is a lack of common asset management work processes.

A look at how the financial sector's concept of Asset Value Management can be applied to the petrochemical industry.

Budget tight? Some Risk-Based Inspection (RBI) risks are too critical to delay. Learn the top 3 RBI risks that can't wait for a budget rebound.

Rate reduction on new projects to support the industry during the current extended downturn.

A look at how RBI adds value whether you are just starting out or transitioning from a traditional methodology.

Transitioning to Risk-Based Inspection (RBI) delivers measurable efficiency and cost savings, whether you have a mature Mechanical Integrity (MI) program or are starting from scratch. See a simple 100-vessel example saving $645,000 per cycle.

How AOC's new AI solution cuts data collection time for Risk-Based Inspection (RBI) projects by automatically extracting and normalizing data from historical engineering documents, achieving very high accuracy and reducing costs.

An update to our original proposal for an API 581 Inspection Plan optimization.

What are equipment/inspection strategies in relation to mechanical integrity (MI) and risk based inspection (RBI)?

What are the hidden benefits of implementing Risk Based Inspection?

Service Inquiry