We literally wrote the book on asset integrity management.

Since 1994, our experts have contributed many of the codes and standards that are the basis of software tools in the industry today. Asset Optimization Consultants uses best-in-class technologies in master data management and data conversion to ensure the trustworthiness of your information. With a systems-level view of reliability across all asset families, your owner operator has the confidence to make critical decisions.

Overview

The trustworthiness of your data is everything, especially in asset-intensive industries like oil and gas. Data determines the productivity of a facility, the level of risk associated with equipment, the capability of an operation, and - most importantly - the level of safety risks to personnel.

Unfortunately, major oil and gas, refining, petrochemical, and chemical manufacturers lose a large chunk of their revenue to unexpected events. In fact, approximately 1 to 1.5% of their annual revenue is lost due to excessive downtimes as a result of unplanned outages.

To protect the trustworthiness of your data, Asset Optimization Consultants applies existing technology as part of a master data management system. The benefits include:

- Accurate, dependable information

- Early and sustainable delivery of value

- Development or improvement of work processes

- Faster, more efficient extraction of critical equipment and piping data

- Ability to anticipate unplanned events before they happen

- Confidence to make critical decisions

What is a Master Data Management System?

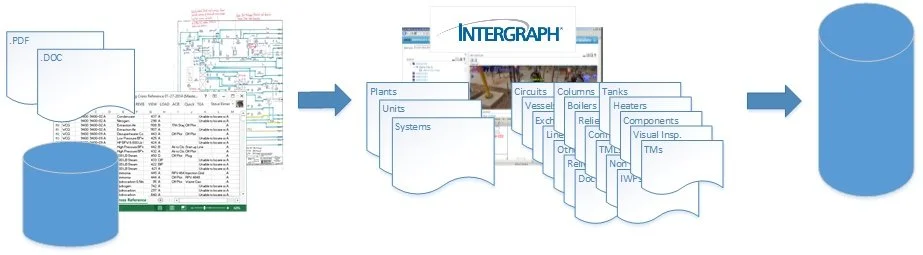

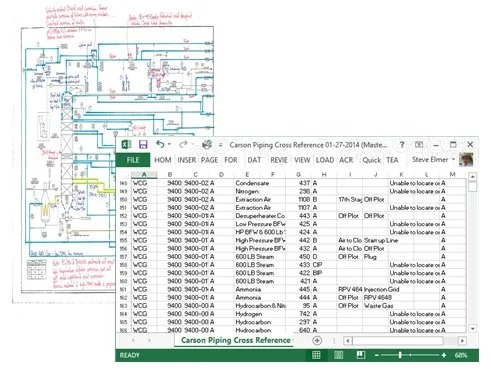

Master data management begins with data migration of your "sources of truth" from the unstructured, document-centric environment of your plant. Our rapid-capture approach includes scanning paper documents, tagging, and reconciling master data according to QA/QC rules.

Data Gathering

Using a combination of partner tooling in conjunction with a handful of internally developed tools we provide an end-to-end solution to data collection, migration, and management.

Working with Intergraph’s SmartPlant/Fusion tool, we begin with the transformation and consolidation of your data which may be scattered across a variety of unstructured documents, drawings, spreadsheets, and databases into structured data that can be easily queried and retrieved.

Data Preparation

Simply gathering the data all into one place, however, is not enough. Most target systems such as Meridium APM and Capstone RBMI have their own host of idiosyncrasies and arcane rules that need to be met. Often times it is also the case that target systems already have enterprise level data from other plants/sites and it is desired that the new data adhere to enterprise-wide rules and norms. We find it is also frequently the case that our clients want to perform additional transformations on their data such as piping systemization which can be difficult once the data is in the target system.

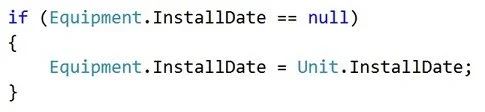

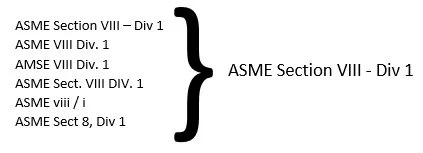

Using tooling developed for us by StarThrower Software, we have the ability to apply a variety of rules and transformations on the fly as the data is prepared to be imported into the target system. These may be as simple as specifying default values when data is bad or missing, but required by the target system. Or may be as complex as mapping and collating your isometric drawings into their respective systems. And it is nearly always the case that source data has multiple values for the same item which you would like mapped into a single value.

Data Import

Once your data has been collected and prepared, it is simply a matter of submitting the output from our RBI Migrator to the target system for import. Whereas in the past this often was a painful trial and error process, alternating between submitting your data to the target system and fixing a bunch of import errors, our RBI Migrator tools mitigate this unnecessary iteration. We ensure that data submitted to the target system for import is clean, consistent, and obeys the various rules of the target system.

Conclusion

Ultimately, the structured data is integrated into the knowledge-centric world of your Owner Operator. In addition to performing tasks related to MI and RBI, our consultants align the knowledge of your personnel through skills assessment tools and training in data management. We also design human performance measurement tools that are specific to the people and work processes at your site.

With best-in-class technologies as part of a master data management system, your Owner Operator is equipped with a systems-level view of reliability across all asset families. The result is confidence in your ability to sustain the trustworthiness of data and to make critical decisions in the event of unplanned events.

Applications

Meridium

We use best-in-class technologies for delivering sustainable RBI programs. As Meridium certified service providers, we have deliver a systems-level view of reliability across all asset families, to ensure you the Owner have the confidence to make critical decisions.

SmartPlant Fusion

AOC utilize Intergraph's SmartPlant Fusion, best in class technology for rapidly finding, capturing, and organizing large volumes of unstructured information. Utilizing AOC's rule base we are able to significantly accelerate this people intensive work process as SmartPlant Fusion helps eliminate duplicates and outdated revisions of documentation and extracts intelligence and establishes links allowing our engineers to readily populate the requisite target data for a RBI (risk based inspection) program.