Asset Integrity Management Assessments

Register

Nothing is scheduled at this time.

Request more information about when this course will be scheduled or inquire about our on-site training.

Overview

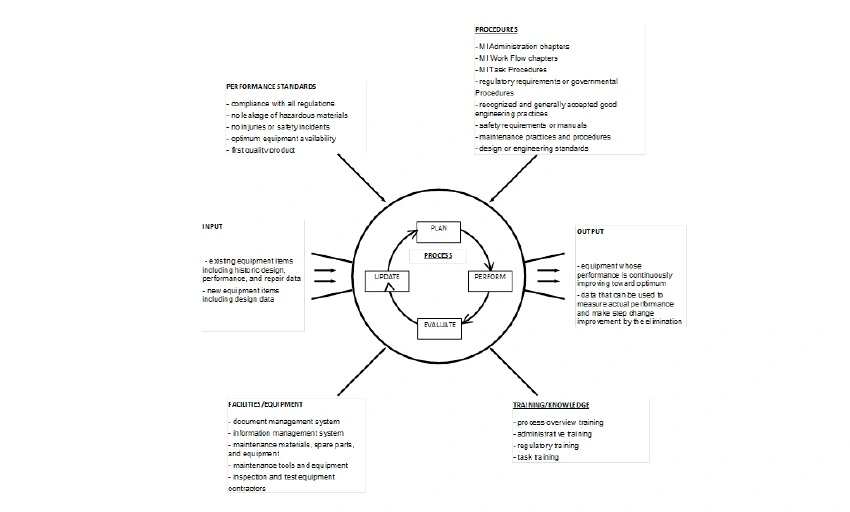

The parts of the MI System Model are:

Inputs - Inputs to MI are:

- existing equipment items to be incorporated into MI including their historic design, performance, and repair data

- new equipment items added later to the process including their design data

- Equipment items are included in MI because coverage is required for compliance with governmental regulations required because the equipment has an impact on key business indicators other than safety

Procedures - MI is defined, implemented, and managed by the written and approved procedures included in the MI Manual and site-specific installation procedures. All procedures should be based on:

- regulatory requirements or governmental procedures

- recognized and generally accepted good engineering practices, such as API, ANSI, SAE, and NFPA standards and practices

- site safety requirements or manuals

- site maintenance practices and procedures

- site design or engineering standards

Facilities/Equipment - The facilities and equipment that drive the MI process include:

- document management system for approval, issue, storage, distribution, and revision of controlled procedures and drawings

- information management system for controlling maintenance data and records, including reports generated within the MI process

- quality assurance system to manage maintenance materials, spare parts, and replacement equipment to ensure they meet the design intent and are suitable for use when needed

- well-maintained tools and equipment

- inspection and test equipment that is in good repair and certified if necessary

- qualified contractors to perform various maintenance, inspection, and testing tasks

Training/Knowledge - Properly trained personnel perform their assignments more efficiently, thereby reducing maintenance costs.

The training for people working to maintain equipment integrity and reliability includes:

- Process Overview Training so they understand a general overview of the equipment, process materials, and area safety information for the area in which they will work

- Administrative Training so they understand corporate, site, and area policies, practices, and procedures necessary to perform their jobs safely and efficiently. This includes MI training

- Regulatory Training so they understand the applicable regulations

- Task Training so they are qualified to perform the tasks associated with their job

Performance Standards - Performance standards describe desired or optimum performance, and are used to develop metrics that measure actual performance against those standards.

Typical performance standards are:

- compliance with all regulations

- no injuries or safety incidents

- no leakage of hazardous materials

- optimum equipment availability

- first quality product

Outputs - The outputs of MI are:

- Equipment whose performance is continuously improving toward optimum. The revised Equipment Plan becomes the input to the Plan step the next time work is performed.

- Data that can be used to measure actual performance and to make step change improvement by the elimination of defects

The Value of System Design - Many maintenance systems focus on one or two of the elements in the continuous improvement model and pay little attention to the others. As a result, maintenance performance suffers and production costs are higher putting an organization at a competitive disadvantage.

Typical omissions addressed in AOC's MI model, for each element include:

- Inputs - design and historic information not available to personnel

- Process - focus on fast repairs with little attention to planning and scheduling, evaluating results, or updating (improving) the maintenance system

- Performance Standards - undefined performance standards or using performance standards that have little significance as a measure of maintenance performance

- Procedures - procedures not in place or uncontrolled

- Facilities/Equipment - no system in place to manage the quality of support facilities and maintenance equipment

Training/Knowledge - no focused training process to deliver the specific training needed by each employee

- Output - as a result of the shortcomings of the other elements, the equipment does not perform as it should and little improvement is attained.

Related Services

Development of maintenance strategies, recommendations, and plans to implement best practices and increase asset life

A maintenance system designed in which elements work together as a quality system for maximum returns

AOC delivers the policies, procedures, work processes, knowledge and actions such as preventive maintenance, predictive maintenance, and condition monitoring tasks.

Related Training

A high level overview introducing Mechanical Integrity and Risk Based Inspection

What are your goals for RBI? How will you measure your success? How will you sustain that success?

How do I use GE APM to perform MI/RBI tasks?

Related Knowledge

A dysfunctionality found in many refineries, chemical plants, and other production facilities, is a lack of common asset management work processes.

A look at how the financial sector's concept of Asset Value Management can be applied to the petrochemical industry.

This is a practical approach to incorporating the new PHMSA gas well rules into your integrity program with the rest of your surface and subsurface assets.

A look at how RBI adds value whether you are just starting out or transitioning from a traditional methodology.

PHMSA has out for comment, draft document information, that clarifies its jurisdiction in relation to OSHA for Midstream Processing Facilities.

Things are always changing. Including your risk profile.

An interesting discussion in which several engineers find common ground.

What are the hidden benefits of implementing Risk Based Inspection?

When working in Brazil please be aware that Brazil has its own Regulatory Standard – NR13 – that covers the minimum requirements for managing the integrity and inspection of steam boilers, pressure vessels, storage tanks and interconnecting pipes.

An example to compliment our earlier proposal for a risk analysis option that allows for individual damage mechanism risk calculation in API 581

Webinar Inquiry

For more information about this course or to inquire about a customized version of this course hosted in-house at our Houston, Texas location or on-site at a location convenient to you, please complete the form below.