Data Migrator facilitates a data mining work process for:

- Setting up asset specific electronic data files including U-1 forms and/or fabrication drawings. In other words, a methodology for expeditiously converting your asset information from a docu-centric environment to a data-centric environment allows you to look at your asset data from anywhere in the world.

Once the scanning process is completed, the electronic files are organized by equipment type (columns, towers, air coolers, heat exchangers, etc) and piping equipment files, including the systemized and circuitized P&IDs as well as specific files for each piping circuit. An example of the electronic data files include but are not limited to:

- As-built drawing

- P&IDs

- Manufacturer's drawings

- Installation drawings

- Arrangement, tube layout, and logic drawings

- Basic equipment design information

- Original specification sheet

- Calculations for sizing the relief device

- Shop testing or calibration record (for relief valves and conservation vents)

- Fabrication data

- Acceptance test results

- Manufacturer's operating and maintenance instructions

- Parts list

- Operating information

- Operating certificate when required

A facility with, say, 400 pieces of fixed equipment, 800 piping circuits and 400 PRDs takes less than three months to complete.

In many cases, owners are initially happy to have their asset data available electronically; however, converting this data to knowledge is a much easier next step as can be seen from the following case study. A southern California refiner was transitioning from one IDMS (inspection data management system) to a corporate RBI program. Over twenty million data fields had to be moved from one data base to another. The total number of assets being converted was as follows:

| Asset | Active | Inactive |

|---|---|---|

| Process Units | 220 | 15 |

| Equipment | 3753 | 3293 |

| Systems | 2763 | 111 |

| Relief Valves | 3871 | 5387 |

| Inspection History | 144860 | 0 |

| Piping - Systemized | 15206 | - |

| Piping - NOt Systemized | 4022 | - |

| Piping Out of Service | 1303 | - |

| Piping Inactive | - | 2669 |

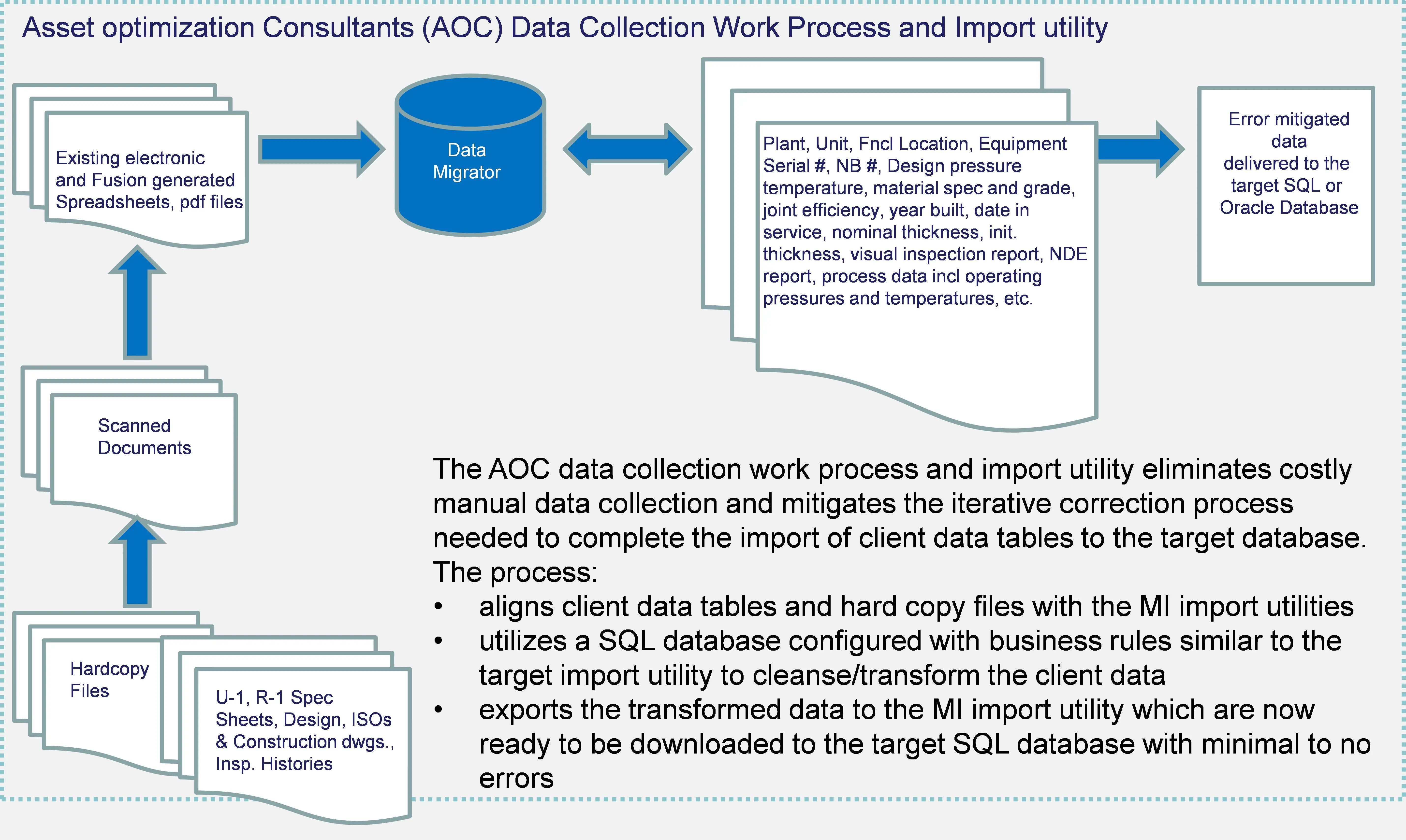

Another major concern of the owner was the cost of renewing the older IDMS license which was considerable and in excess of several million USD. Given a time frame of less than six months to complete the transition and successfully complete UAT (User Acceptance Testing) of the target RBI database, AOC consultants utilized the data migrator tool from StarThrower Software, to expedite the data mining process and cleanse the data prior to exporting to the target IDMS SQL database. The project was completed in five months saving the owner millions in renewed licensing costs. For additional information on this case study please contact us.

Case Study Inquiry